In the age of digital transformation, businesses are proactively searching for methods to enhance their processes and boost efficiency. One such solution is adopting inventory management systems, which promise to streamline processes and transform supply chain management. However, many companies struggle to fully embrace these systems, despite their potential benefits. As a result, resources often go underutilized, and opportunities are missed.

Global statistics reveal that the success rate of IT projects stands at 31% (based on research conducted by the Standish Group in the 2020 CHAOS Report). The remaining 69% represent either problematic IT projects or outright failures. This gap between expectations and outcomes highlights a critical factor - the human element. Employees play a pivotal role in implementation, and their willingness to accept or resist change can determine the success or failure of adopting an inventory management system.

When introducing new technological solutions, businesses often overlook the emotional and psychological impact on their workforce. Employees are required to adapt to new tools and undergo retraining, which can create feelings of uncertainty and stress. Managing the human aspects of a project is crucial to avoid project failure, as 69% of IT initiatives have failed due to this.

In this article, we share our experiences with the common challenges and objections that companies face from employees during deployments. We also offer suggestions on how to involve teams to guarantee successful implementation.

While the advice primarily targets project owners, it also benefits vendors. Vendors, even if contracted for specific outcomes, lack the authority to directly influence users.

The IT Department

The IT team has a lot on their plate, as they need to juggle the upkeep of infrastructure along with other crucial responsibilities. Given IT’s heavy workload, it's not surprising that they sometimes miss deadlines or have to deprioritize requests. Whether the implementation is done in-house or led by vendors, the internal IT team is always involved. Missed timelines are a frequent pain point. The only remedy is to ensure that the project lead has sufficient authority and leverage to maintain priority with IT.

Procurement and Logistics Teams

As the direct end-users interact daily with the new system, the Procurement and Logistics Teams require extra attention to change management.

Sabotage often stems from:

- Attachment to Existing Tools: Employees accustomed to current tools and processes may be reluctant to switch to a new system requiring significant learning effort.

- Fear of Replacement: Some may worry that technology could make their roles obsolete, causing resistance.

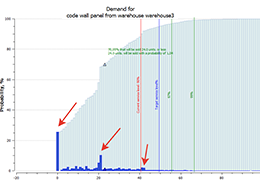

- Distrust in Unfamiliar Calculations: New systems often involve different calculation methodologies, which employees may view as questionable and unreliable.

Procurement specialists, who have experience but are resistant to change, usually do not readily embrace new tools. Mitigating the first two risks requires early, transparent communication. Leadership should meet with teams, explain the rationale for change, and allow questions. It's crucial to stress that the system aims to augment employee capabilities rather than replace anyone. Share specific productivity projections, like reducing calculation times from hours to minutes.

Additionally, explain how automation may shift responsibilities. In our experience, automation often alleviates procurement employee burnout by freeing up time for value-added analysis, market research, supplier relations, etc.

Secondly, schedule extended demo meetings between users and vendors before launch. These hands-on previews build an understanding of features and workflows, demonstrating how the system supports team objectives. Proper framing reduces anxiety about the rollout.

Building Trust in the Calculations

User adoption also relies on trust in the unfamiliar system's math. New tools often bring new methodologies that may be rejected as erroneous without proper onboarding.

To reduce the risk of sabotage, we recommend the following plan:

- Opt for robust training led by vendors with follow-up assignments and issue tracking. Customers should funnel trainee questions to vendors for detailed explanations. A lack of questions indicates potential comprehension gaps.

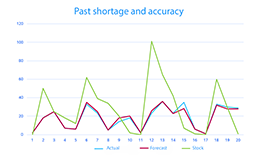

- Conduct parallel testing of calculations after training, reviewing significant variances jointly with vendors. Though initially time-consuming, this builds faith in the tool's accuracy.

- Cultivate Internal Experts: Establishing a competence center within the company for the new system can create a network of early adopters. These employees can share their successful experiences with others, fostering trust in the new technology.

In summary, critical factors include early stakeholder engagement and maintaining an open dialogue between users, leadership, and vendors throughout implementation.