Retailers all over the world have to adapt to new market realities and changes in consumer behavior by taking a new approach to analytics and demand forecasting. Adopting new technologies has become a matter of business survival rather than a capricious digitalization fetish.

To keep your store shelves full and adequately predict consumer demand, consider using a checklist from Forecast NOW!, an experienced inventory management and demand forecasting software developer.

About the company: Forecast NOW! has a corporate R&D department and more than 12 years of expertise in studying and testing various demand and inventory forecasting techniques for various retail sectors ranging from neural networks and genetic algorithms to probabilistic models.

Point-of-sale inventory planning requires significant labor inputs when it comes to statistics and sales history clearing. For correct calculations, many factors should be taken into account, e.g.: seasonality, promotions, product shelf life, risk of supply disruptions, and large one-time orders. Moreover, doing it manually will be very expensive if not impossible. Let us consider the main problems causing empty shelves in stores and how to avoid them.

Orders: Seller's Intuition vs. Reality

Products are ordered based on a "gut" feeling, and then orders fulfilled post-fact after a customer has requested them. The products are delivered to a point of sale in a few days, taking into account the supplier processing time, lead time, acceptance, and visual merchandising. In case the store is connected to a distribution center (DC), the lead time increases further. If the store takes product directly from the DC, other points of sale may lose the stock they were counting on.

Solution

The seller can apply standard basic techniques calculated in Excel. To begin with, we can use average daily sales, and then methods developed by Jon Schreibfeder. These were founded on corporate policy conducive to the effective inventory management, as well as on hardware and software, and knowledge of employees.

Ideally, the order would be better handled by a specialized system rather than an individual. It is important to make calculations in advance to account for lead time. The program takes into account the timing of the entire supply chain, parameters of promotions and other activities. For example, someone has made a small-scale wholesale purchase and one store takes the entire stock of products from the DC, while other points of sale remain out of stock, because they do not have an automatic calculation and forecasting system.

Different Tools for Different Levels of Supply

Items are ordered to a store based on approximate estimation, while the distribution center uses an automated reorder system. Consequently, these systems are not synchronized with each other, resulting in in-store stockouts.

Solution

Here, we need to centralize purchases so that a single tool is used at all levels of supply, whether an Excel file, specialized software or other calculation methods.

It is essential to use a single system capable of calculating most of the risks. For example, a system that factors in large one-time orders or upcoming sales promotions. Without this, the store can end up ordering 4 times more goods than needed due to mistakes in forecasting. Then the other points of sale will have to distribute products to correct for the resulting, yet preventable, shortage.

Product Stock-Outs During Sales Campaigns

Due to the lack of coordination between departments, products are not reserved and placed on shelves in due time during a promotion. Departments may use different forecasting systems, which eventually leads to a stockout.

Solution

First of all, the marketing department and the procurement department should collaborate by using a single forecast document. Promotions should be better planned in advance with a focus on single-system accounting that accounts for additional inventory for promotions and aligns ordering accordingly. We need to predict peaks in demand based on historical data and place the products on shelves in advance. The effect of a sale may vary greatly depending on the discount rate, promotion type, and mechanics.

No Adjustment for Seasonal Demand Fluctuations

This involves both seasonal peaks, since, for example, swimwear sells better in summer and fur coats in winter, and holidays and extreme weather-driven sales peaks.

Solution

Products can have both monthly and weekly seasonality. For example, alcohol sells faster on the weekends. There are situations with floating seasonality, for example, seasonal flu products. We also need to consider holidays and high and low-temperature periods when planning. Therefore, sellers should apply seasonality analysis methods and seasonal trend models, such as the Holt-Winters Method. If a seller does not know whether a product shows seasonal sales, then the autocorrelation function available in Excel should be used.

If we have historical data on all types of seasonality, we can forecast future fluctuations in demand. It is worth noting that a large number of items (SKUs) makes hand calculations troublesome and an automated solution will help capture all possible seasonal effects.

"Invisible" Products

When products are in stock but not on display, we refer to the situation as shrinkage.

Solution

Here we utilize the frequency analysis method, i.e. Here we utilize the frequency analysis method, i.e. we calculate with what frequency the product is sold. For example, in 95% of cases, it is sold every day, in 3% – every other day, and in 1% – after 5 days. If we take 98% as a confidence level, then the sale in 5 days raises suspicions. When sales time is longer than usual, for example, more than 3 days, then shelves should be checked.

Each store has an inventory turnover, i.e. a period during which a shelf becomes empty. a period during which a shelf becomes empty. If there is not enough staff at the point of sale, the shelves are not simply replenished in time. There also may be some other reasons for stock not making it to the shelves, such as product defects or only virtual product availability; or the product can be reserved for the client and unavailable in the sales area. There can also be the so-called resorting, when one product was sold, but the other was written off. It is always easier to track such things with an automated system.

Product Availability Without Profit Orientation

The seller tries to ensure maximum product availability without focusing on profit.

Solution

Empty shelves in the store are not always a bad thing. We need to focus on profit and assess risks in advance: how much will be lost due to a stockout and how much if some products spoil when there is no stockout. This approach does not apply to branded and anchor products (those to get which people come to a store and then purchase the other items). Sometimes it is more profitable for a store to keep a shelf half-empty or reduce its size than fill it.

Shelf Life Expiration

A product is about to expire, therefore it has to be written off, and the shelves become empty. Or buyers will refuse to buy items with 20-30% of their shelf life left, and the shelves remain stocked.

Solution

You need to track the shelf lives of both products and product batches when purchased from the supplier. If a store has 5 product batches, it is necessary to predict which products and which quantities will remain with a breakdown by batches. The products with a shorter shelf life should be displayed in the sales area on a first-priority basis. It is difficult for an individual to make such calculations, since many stores do not keep a record of the batch statistics and product shelf life at all.

Effective shelf life should be used for forecast calculations. Thus, if the product shelf life is 10 days, the effective shelf life is half, i.e. there are 5 days left for sale. there are 5 days left for sale. The first task in forecasting is to understand what stock will be available by the time of order delivery to the store. Upon the effective shelf life expiration, the stock should be set to zero.

No Division into Retail and Wholesale Warehouse

There is no division into wholesale and retail sales, which results in a shortage of products in the store.

Solution

Inventory should be divided into several virtual warehouses — wholesale and retail, though there may be one physical warehouse. The forecast model should calculate the demand for the two virtual warehouses separately. Thus, a large order will be shipped from the virtual wholesale warehouse, and physical stock will also be available in-store.

Incorrect Safety Stock Calculation

The problem is that companies often take normal distribution to calculate safety stock — using standard deviations or the three-sigma rule.

Solution

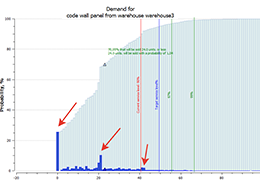

The incorrect calculation of safety stock by standard deviations results in a shortage of some commodity items with a surplus of others. The bootstrap method for setting safety stock levels is the best for forecasting purposes.

The normal distribution is suitable only for 4-6% of regular-demand items, such as bread, milk, sugar, and similar products. It is not applicable for products with intermittent demand, such as household cleaning items, housewares, electronics, or building materials. We encourage companies to use an empirical (or experience-based) unique distribution of demand for each product at each point in time. Among other things, it makes sense to introduce a unified safety stock calculation procedure corresponding to the business development level.

Stockout Caused by Supplier

Or when there is a short shipment to the store.

Solution

Sellers should regularly analyze and track how many items were ordered, how many were actually delivered, and how many have the necessary shelf life and are non-defective. If the service level does not meet the seller’s expectations, then the seller must either find ways to work with existing suppliers, or negotiate new contracts.

Lack of Coordination Between the Departments

Each department applies its own procurement procedure and does not share information with colleagues.

Solution

Let's imagine the marketing department has planned a promotion, but information on its terms and conditions was not communicated to other departments - or was communicated late. Marketing specialists have come up with a forecast, given it to the procurement specialists, who, in turn, have somehow plugged it into the system and ended up with different order sizes for the promotion. There is a need for a single harmonized system for all company departments' order forecasting work. '

Sometimes an impression of shortage and empty shelves is created deliberately so that buyers feel a sense of urgency about making a purchase, assuming that stocks will soon run out. Companies should adopt different strategies for visual merchandise planning. They may vary depending on product type, supplier arrangements, visual merchandising space and priority.

Some key determinants of demand and stock-on-hand may be ignored when it comes to in-store stockout causes. This includes the human factor, such as employee error, and communications issues when company departments are unable to agree on and employ the same tools for forecasting. Finally, there is the methodological factor when incorrect calculation methods are used or there is no division into wholesale and retail sales, for example.