Determining the right time to implement an inventory optimization system is not straightforward. On one hand, a company must reach a certain level of maturity and be ready for such changes; otherwise, time and money will be wasted. On the other hand, delaying this decision risks losing market positions to competitors. Let's consider 6 signs that it's time to think about implementing a specialized inventory management system.

1. Excess of Some Goods and Shortage of Others

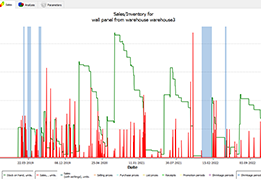

The first and most obvious sign is having excess stock in some product categories while facing shortages in others. It can be challenging to determine the exact percentage of shortages, but the company loses profit if popular items are often missing from shelves. The same applies to excess stock.

If this is a systemic issue and occurs regularly, it's a clear indication that a change in approach is needed - whether it's implementing a specialized system or hiring a consultant.

2. Lack of Transparency in Inventory Management Processes

You are unaware of why certain goods were ordered in specific quantities and can't verify it either. Each employee relies on their calculation methods, expertise, or agreements with suppliers.

You can't obtain real-time operational information about the number of orders, stock in warehouses and branches, transfers, promotions, etc., without extensive report preparation, often impossible to decipher without the responsible personnel.

Lack of transparency and dependency on specific employees for efficient operations is a reason to systematize activities.

3. Unawareness of Key Inventory Management Efficiency Indicators

You don't know your inventory turnover, first and second-type service levels, lost profit, missed demand, stock profitability, etc. Usually, you can't calculate them, or it requires the involvement of several employees and one to two weeks.

Knowing key KPIs allows a company to compare itself with industry benchmarks and understand how effectively it manages inventory and what improvements can be made. For more on this, refer to our article “Key Indicators of Inventory Management Efficiency.”

4. Purchasing Department Staff Constantly Overloaded and Prone to Errors in Orders

Is it familiar that your purchasing department is constantly occupied with forecasts, calculations, and endless approvals, with no time to analyze the market or track new trends? During peak periods, like seasonal spikes or preparing for the New Year, the department works excessively, often overtime, and remains in a constant state of emergency.

With such intensity, the likelihood of making mistakes is very high. Sometimes these errors can be very costly for the company – leading to lost profits or a pile of unsellable stock, which is then sold at a discount or written off entirely.

Unfortunately, without automating some operations, the company will have to keep hiring more and more employees as it grows, and the cost of mistakes will only increase. This is a significant reason to consider implementing a specialized system.

5. Poor Quality of Forecasts

The accuracy of forecasting often measures the effectiveness of inventory management. If you're dissatisfied with the quality of your forecasts, there are two ways to improve it.

The first option is to hire expensive experts in your field, suitable for companies with a small number of SKUs. Otherwise, the staff will grow, and the annual labor cost can be comparable to purchasing a perpetual license for specialized software.

The second option is to implement an inventory management system.

6. Orders to Suppliers are Often Suboptimal Due to the Need to Consider a Large Number of Factors

Calculating the necessary stock to meet demand is only half the battle. It's unlikely to be as simple as just ordering it from suppliers. In real-life conditions, there are always some constraints: delivery quantum, minimum order quantities, minimum budget, transport capacity limitations, cost of processing an order line, etc.

All these need to be calculated to select the optimal suppliers and delivery conditions; otherwise, all the previous work is in vain. This requires significant effort, so companies often have to agree to the supplier's terms, which aren't always optimal. Implementing an auto-order system can change this situation. It will automatically calculate the most advantageous options primarily benefiting the company.