In this article, we will detail how Forecast NOW works!

Data Upload

Before generating orders, data must be uploaded into the program from the client's accounting system. This can be from systems like 1C, SAP, Oracle, or any other system.

Types of data uploaded into the system:

- Sales, stock, and implementation price reports.

- Groups and properties of goods.

- Information on the dates of arrivals.

- Information about marketing promotions: when they occurred and which product categories they affected.

- Supplier data: their minimum volumes and order amounts.

- Data affecting orders: shelf life, packaging capacity, volumes and weights of goods, minimum batches, multiples, and other nuances of supply.

Data Accuracy Verification

All data uploaded into the program undergoes a verification process. The syntactic correctness of the data file is checked. Additionally, a basic logical check is conducted, for example, to ensure there are no negative sales figures. If errors occur during the process, the program signals them.

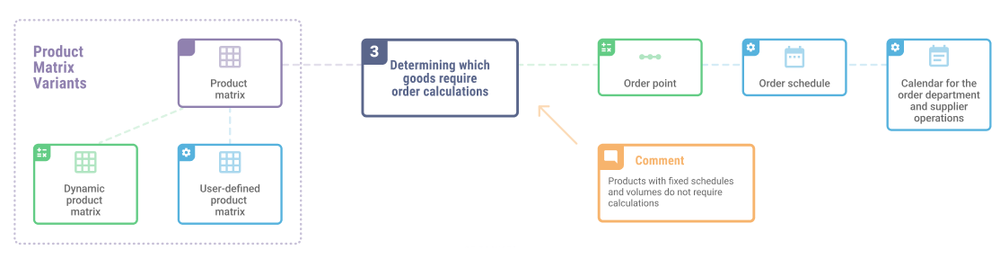

Determining Which Goods to Order

Initially, the program examines the product matrix. This matrix can be uploaded from the accounting system or manually created by the user. The user specifies which product positions at which retail locations are included in the matrix. The program can also dynamically determine the matrix. It checks how well products are selling at retail points and suggests either removing them from the assortment or adding more.

In addition to the product matrix, we need to know other order parameters:

In addition to the product matrix, we need to know other order parameters:

- Schedule: the days when orders are usually placed.

- Calendar of the order department and supplier: if the supplier has a day off, the order will need to be placed earlier.

- Order point based on reaching the minimum stock level: If the current stock is sufficient to meet the order point, an order calculation will not be performed.

Once everything is verified, the program will generate a list of goods for which orders need to be calculated.

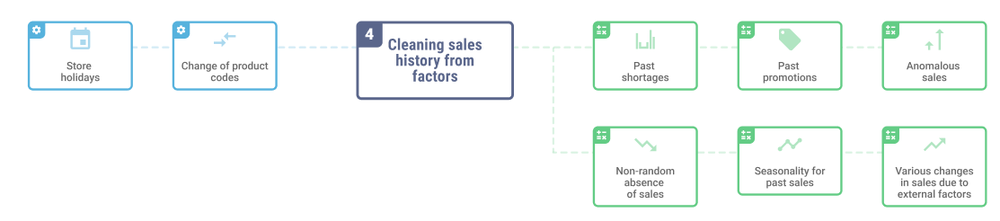

Sales History Cleaning

The uploaded sales history is not always suitable for forecasting future demand. Past periods may have experienced shortages, marketing promotions, or, for example, anomalous spikes that affected sales but distorted actual demand. Therefore, before modeling future demand, it is necessary to reconstruct past demand from the sales history.

The program cleans sales data from the following factors:

- Past Shortages: There may have been times when items were out of stock, so there were no sales. The program identifies shortage situations and excludes them from modeling.

- Past Marketing Promotions: Promotions may have caused items to be purchased more frequently than usual. Forecast NOW! calculates the impact factor of promotions on demand and cleans the sales data accordingly.

- Non-random Absence of Demand: Sales may have been lower or absent due to issues like detached price tags or items not being displayed properly.

- Anomalous Sales: A single customer might purchase a month's supply of a product, causing a significant spike in sales. The program smooths out these anomalies.

- Variable Seasonality: Sales increases during holidays or specific events.

- Sharp Changes in Sales Due to External Factors: For example, a pandemic.

Additionally, during the cleaning process, the program takes into account store holidays and changes in product codes, if applicable.

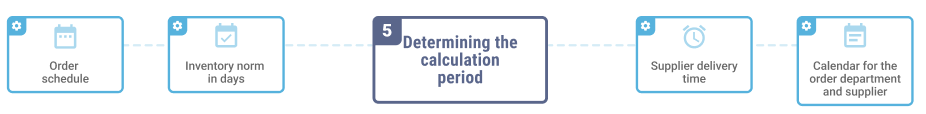

Determining the Calculation Period

At this stage, it is crucial to determine how many days' worth of inventory needs to be maintained. By default, Forecast NOW! is aimed at increasing inventory turnover.

The program analyzes the order schedule and delivery timelines from suppliers. These parameters can be loaded from the accounting system or set directly in Forecast NOW!. Orders are typically placed from one delivery to the next. Additionally, a safety stock can be included to account for potential delivery delays, or a specific norm of goods in days can be set for a particular supplier or group of goods.

Thus, the program determines the period for which an order should be made.

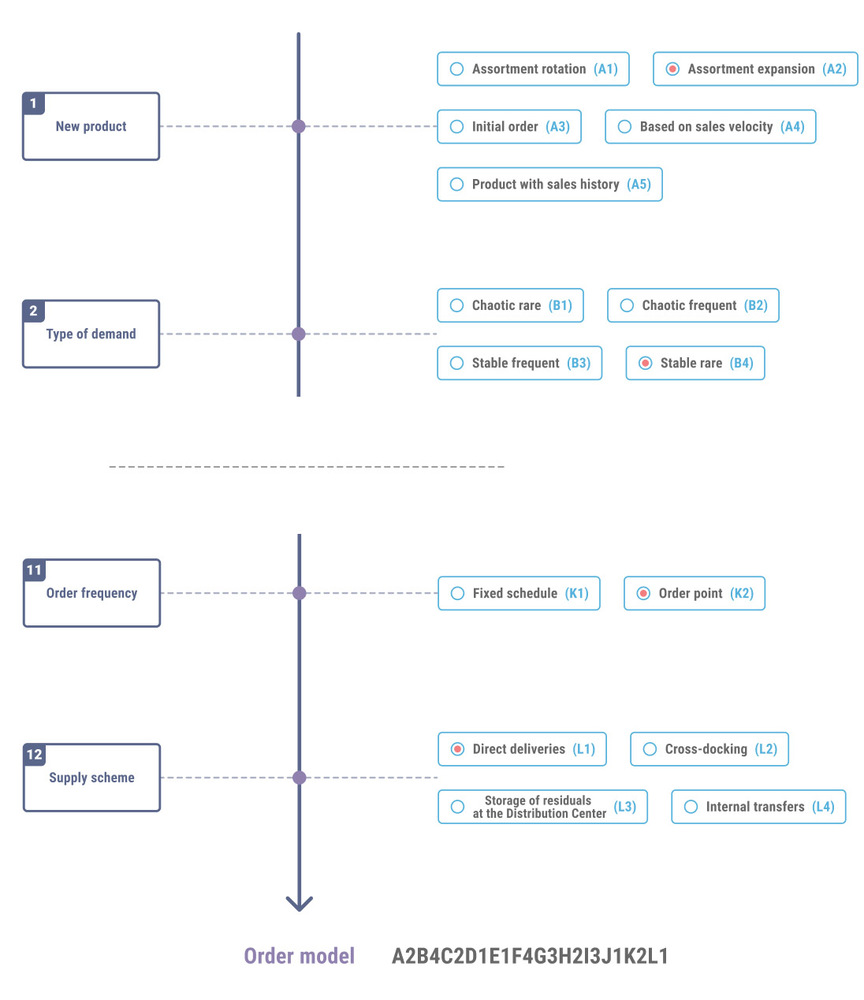

Automatic Selection of Order Model

Forecast NOW! automatically selects the optimal order model for each SKU based on 12 factors and their variations.

The following factors are considered:

- Product novelty

- Type of demand

- Past shortages

- Seasonality of the product

- Necessity to consider shelf life

- Need to forecast promotions for the product

- Method of purchasing for promotions

- Type of service level

- Method of setting the service level

- Supplier selection process

- Order frequency

- Supply scheme.

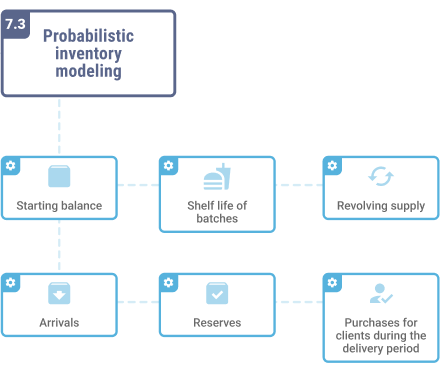

Unmet Demand Calculation

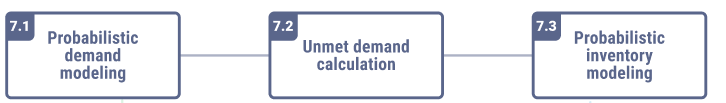

After selecting the optimal order model, the program employs probabilistic forecasting methods to estimate future demand for each product. All types of seasonality, service levels, and promotions are considered.

Forecast NOW! computes the demand forecast not as a single number, but as a set of probabilities, i.e., the likelihood of different demand volumes occurring. For each product position, more than 50,000 experiments are conducted.

For more details on how this works, we have written an article on probabilistic forecasting.

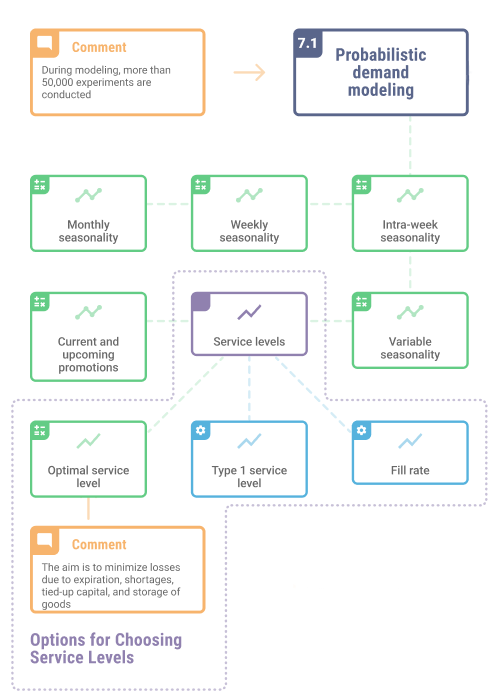

Next, the program calculates what inventory might be in stores and warehouses for the future period, taking into account:

- The initial inventory already on hand.

- Incoming shipments and the dates when goods are expected from suppliers.

- Shelf life of batches.

- Reserved stocks.

- Purchases made for clients during the delivery period.

- The turnover rate of supplies.

Knowing the demand forecast and the inventory forecast for the future period, the program determines the optimal order volume.

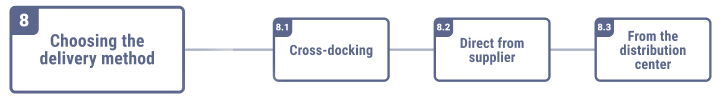

Choosing the Delivery Method

For each product position, Forecast NOW! selects a predefined delivery method. There are three options available:

- Directly from the supplier

- Cross-docking

- From the distribution center.

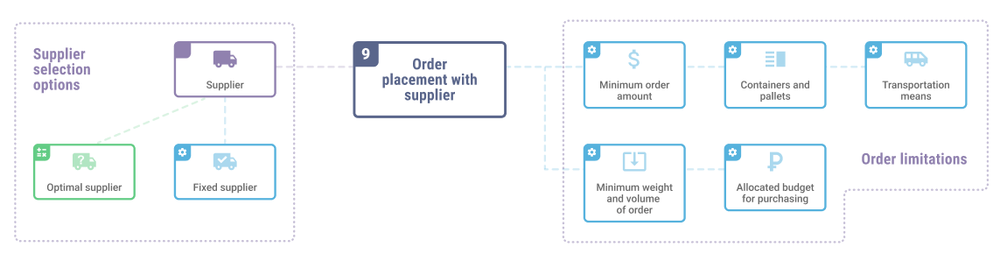

Order Placement with Supplier

The final stage is placing the order with the supplier. The program takes into account any limitations the supplier might have. These could include:

- Minimum order amount

- Containers and pallets. For example, a container must be fully filled, or a specific number of pallets must be ordered.

- The order must correspond to the transportation means available.

- Minimum weight and volume of the order.

- A specific budget for purchasing that must be adhered to.

Additionally, the program can pre-calculate the optimal supplier for a specific product.

Additionally, the program can pre-calculate the optimal supplier for a specific product.